Differences between a brushed motor and a brushless motor.

In our previous article we looked at the main differences between a DC motor and an AC motor.

With this article we will deepen the substantial differences between brush motors and brushless motors.

Brushed motors

The rotor of electric brush motors is composed of a cylinder of ferromagnetic material on which the armature windings are housed in special slots.

When the rotor is in motion, an electromotive force is generated at the ends of the windings.

Mounted on the same rotor shaft is the collector, consisting of copper lamellae; these blades are arranged to form a cylinder, and are in electrical connection with the conductors that make up the armature windings. The collector is therefore formed by lamellae isolated from each other by a dielectric.

The stator, which is the fixed part of the motor, has the task of producing the magnetic flux necessary for its operation. It is made of ferromagnetic material and the pole pairs are generated by the permanent magnets.

In the brushed motor, the collector-brush system is the most delicate part of the system.

Advantages of a Brushed motor

- Simplified wiring

- Possible direct connection to the DC power supply

- Good acceleration response and low rpm

- Low cost

Brushed motors are used in automotive applications, medical applications, automatic warehouses, vending machines, pumps, video surveillance systems, etc.

Brushless motors

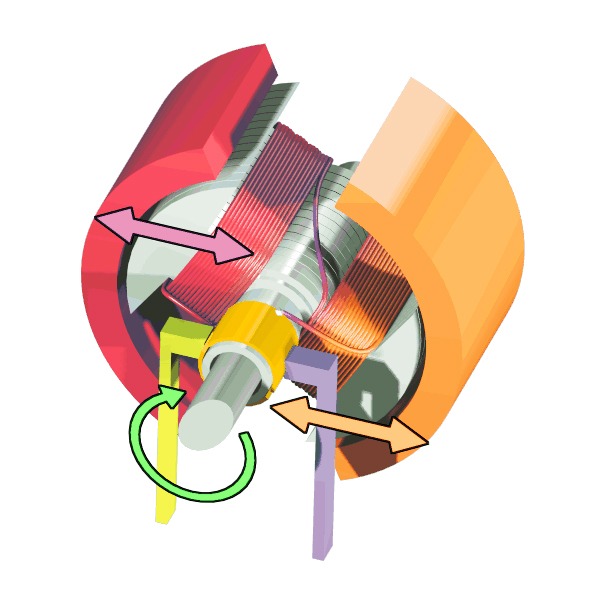

Brushless electric motors basically have the same operating principle as brushed motors; however, they differ in their mechanical construction: if in brushed motors the windings are on the rotor, in brushless motors they are in the stator, and the magnets are glued to the rotor (the type of magnet used determines the performance of the motor).

This solution does not have components with sliding contacts that generate friction, thus making the brushlss motors more robust and reliable.

For operation, a drive is required that controls the switching of the current, and therefore the rotation of the magnetic field.

To make electronic commutation possible and determine the rotor position, brushless motors are equipped with a sensor, usually an encoder or a resolver.

Advantages of a Brushless motor

- reduced maintenance;

- greater reliability;

- wide range of speed variation;

- higher yield;

- better thermal dissipation;

- more compact with the same power;

- low inertia and high dynamic performance.

Brushless Motors are used in all those applications that require precise and fast movements. For example automatic machines, robotics, medical machines, packing and packaging machines.

Garnet offers a wide range of brush and brushless motors, which can be consulted on our website in the products section.

For more information contact us at info@garnetitalia.com