Fuji Electric Co., Ltd. announces the launch of the new 7th generation of power semiconductors X series IGBT-IPM designed to contribute to greater energy savings and reducing power loss in industrial manufacturing equipment.

To improve productivity and automate production, the manufacturing industry is increasingly using machine tools and industrial robots. But, in a scenario where global warming is an important issue, finding production equipment that takes high energy savings into account has become a challenge.

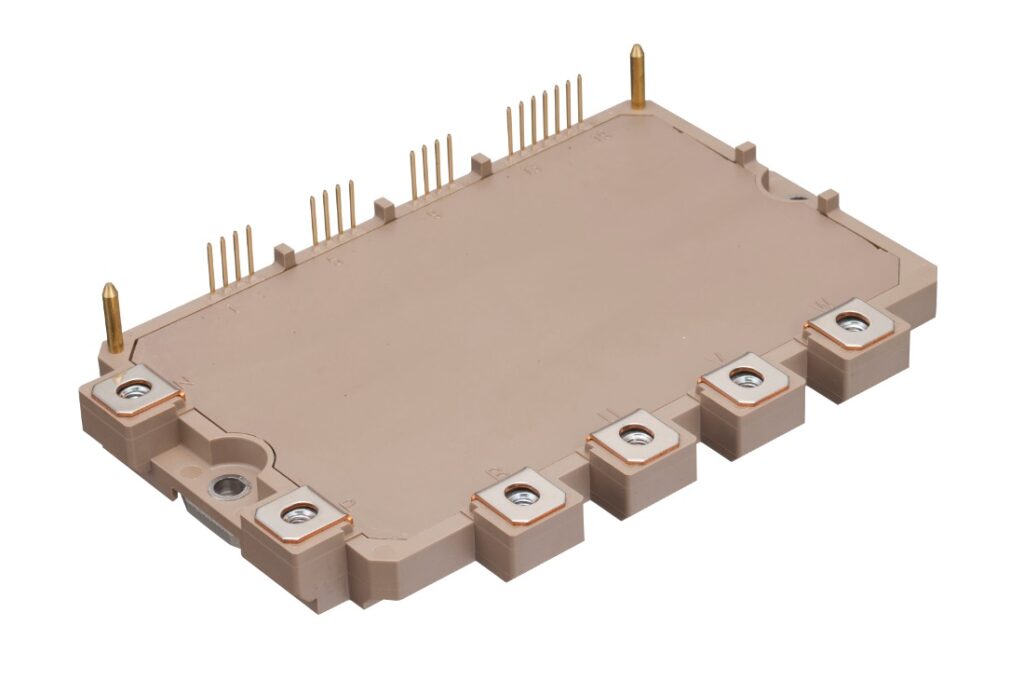

Fuji Electric’s IGBT IPM modules enable greater energy savings thanks to high performance, and permit low power losses due to reduced thickness of the device and the miniaturization of the surface structure.

In traditional power semiconductors, as the operating temperature of the product increases, the switching speed generally decreases and the power loss increases. Conversely, in Fuji Electric IGBT modules the power loss is reduced by using an IC that controls the IGBT drive and prevents the switching speed from decreasing under high temperature conditions.

Also, compared to the previous Fuji Electric V series IGBT-IPM model , power loss and heat is reduced by approximately 10%, and the footprint area has been reduced by up to 54% .

The IPM IGBT is equipped with a protection function to prevent failure due to overcurrent or overheating. When the device temperature exceeds 150 ° C, a first warning signal is emitted, while when 175 ° C is reached, the overheating protection is activated and the switching operation is interrupted, thus avoiding failures and unstable operations.

Thanks to its high safety and reliability, Fuji Electric IGBT IPM modules are widely used in machine tools, servo controls, industrial robots, commercial air conditioners, elevators, and many other fields of application.