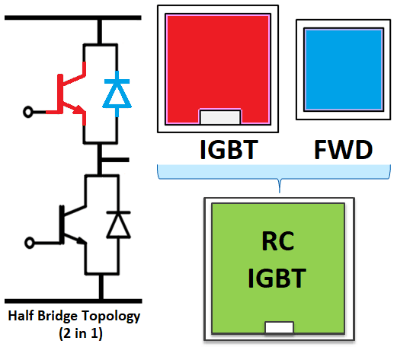

reverse-conducting (RC) IGBT modules

Fuji Electric has developed a 1200V reverse-conducting (RC) IGBT modules based on the company’s latest thin wafer process.

The 1200V RC-IGBT enables increased module ratings:

- upgrading a Dual-XT package from 800A to 1000A,

- upgrading a a small power integrated module (PIM) from 35A to 50A,

- upgrading a PrimePack (TM of Infineon) from 1800A to 2400A.

At the same time, the reduced temperature ripple effect in power cycling improves the reliability of the modules.

The performance of this RC-IGBT shows the same relationship between conduction loss and switching loss as Fuji’s 6th generation conventional IGBT and FWD.

In addition its trade-off can be optimized for hard switching by lifetime killer.

Calculations of the hard switching inverter loss and chip junction temperature (Tj) show that the optimized RC-IGBT can handle 35% larger current density per chip area.

In order to utilize the high performance characteristics of the RC-IGBT, Fuji has developed a new compact package that has low thermal impedance and high reliability.

This module can handle up to 30% higher current than conventional modules at a smaller footprint.

Advantages of the new package include:

- Compact:

conventional package uses Aluminum wire bonding and a circuit pattern on the DCB substrate for the connection between chips and terminals. These methods need a certain amount of area for the wire bonding and the circuit.

The smaller dimensions of the chip RC – considering IGBT + FWD – optimize the internal area and the related connections to build the module and, at the same rating, the overall dimension of the module will be smaller.

- Low thermal impedance:

the new structure uses Si3N4 for insulating material, which thermal resistance is less than half of conventional materials like Al2O3.

In addition the new structure uses a thick copper plate on both sides of ceramic substrate.

These copper plates effectively spread the heat from the chips to the cooling fin. As a result the thermal impedance of our new structure is much lower compared to conventional structure.

- High reliability:

regarding the reliability of an IGBT module, power cycling capability has the biggest impact.

In the power cycling test, due to the different temperature coefficients, all the material used in the module construction are prone to potential problems; among them the wire bonding on the chip and the solder layer between chips and the DCB substrate are some of the weak points of the conventional structure.

The new package is using new materials thought to efficiently deal with the higher temperatures generated by the higher currents the module is able to manage.

Because of this the power cycling capability is better than the one provided by the conventional modules and this guarantee higher reliability and longer lifetime.

The module footprint of the new package is smaller than that of the conventional package and the chip size of the downsized RC-IGBT is 26% smaller than that of the conventional IGBT and FWD.

The Rth(jc) of the downsized RC-IGBT assembled in the new package is much lower than that of the conventional IGBT assembled in conventional package and this improves the chip heat dissipation.

Fuji Electric believes that the combination of the RC-IGBT and the revolutionary package is promising candidate for the downsizing of IGBT and increasing the power density of the complete inverter systems.

For more information about RC-IGBT modules don’t hesitate to contact us at info@garnetitalia.com