Thanks to the continuous improvement process undertaken over the last years, and thanks to the consequent continuous evolution, we gave Garnet an extra kick. So we have renewed and increased our magnetic measurements laboratory (used for incoming and outcoming quality inspection) by adding an Automatic Hysteresisgraph, made in Italy by Laboratorio Elettrofisico Engineering.

What is it and what does it do?

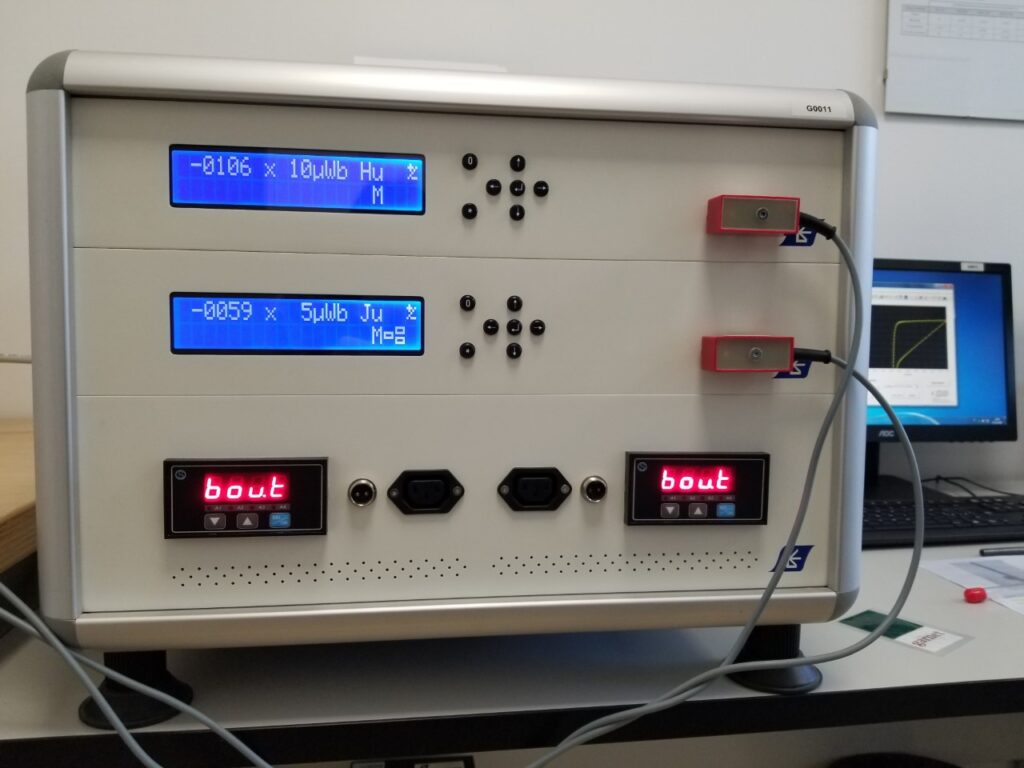

Composed of a yoke in which the polar shoes generate the magnetic flux, a cabinet with two flowmeters and a computer with management software, it is a machine that allows to accurately examine the physical and magnetic properties of any permanent magnet and therefore can determine the actual grade of the tested magnet. Below are the two main activities that are performed regularly or can be performed at customer’s request by customizing the tests:

1. Incoming inspection: When the production batches or the prototypes arrive from our partner factories, (destructive) tests are made on some samples to verify if the batch meets our requirements and therefore the specifications requested by the customer. These tests are very important to certify the quality of the magnet supplied and to ensure that our customer can receive the magnet according to the use in his application, since it is always an important component and must always be calibrated ad hoc. The reports of these tests are regularly provided to our customers with the first delivery batch.

2. Customer’s samples inspection: With this machine, we can test the samples provided by our customers to verify if the magnet complies with the specifications developed by the customer when designing or modifying their application. The test is always documented through the Test Report.

The magnets tested on the Automatic Hysteresisgraph will no longer be usable in the application, except for Ferrite (sintered or injected) and AlNiCo (melted or sintered) magnets. The demagnetized samples will be archived after the test for further verification of the mechanical properties.

Traceability of the production batches (incoming and outcoming)

With this machine and in collaboration with our partner factories, we created a new internal process that provides full traceability of the production batches, with supply batches to our customers, starting from the delivery of raw material at the factory. This allows us to provide to our customers a high level of quality and reliability.