Main magnetic materials: Neodymium, Samarium Cobalt, Alnico and Ferrite

A permanent magnet is a body that generates a magnetic field and allows you to move ferromagnetic materials and attract or repel two magnets.

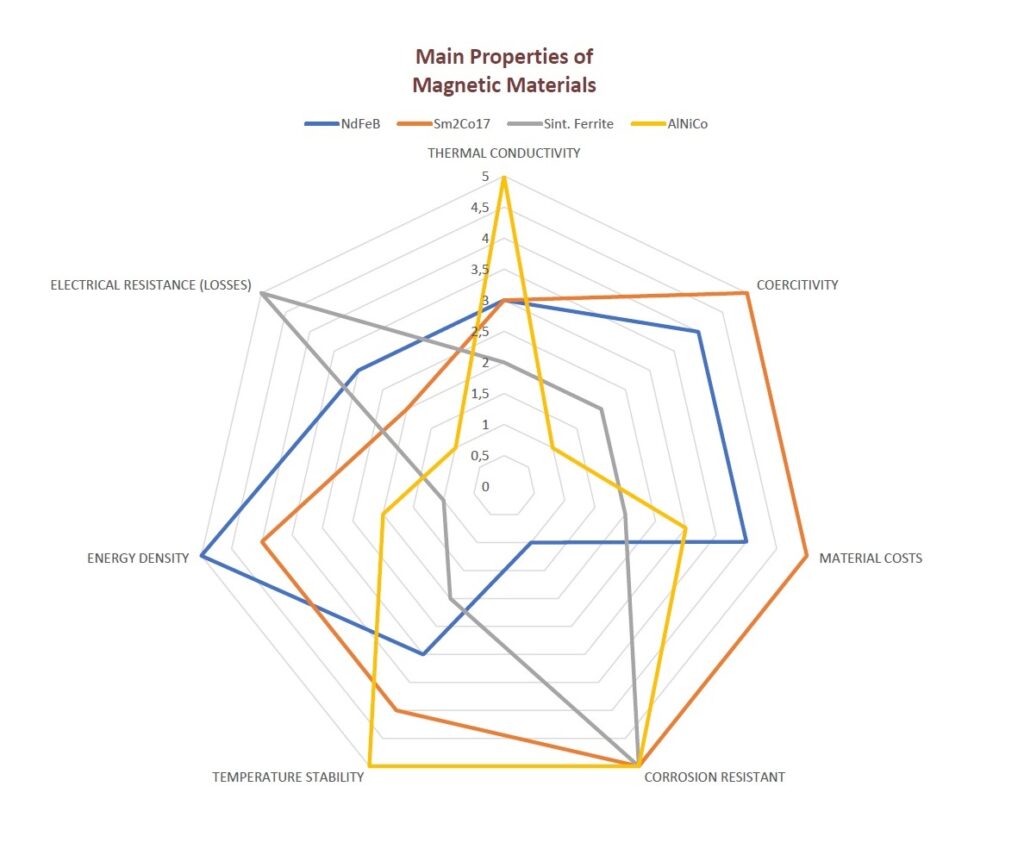

The most popular magnetic materials include sintered Neodymium (NdFeB), sintered Samarium Cobalt (Sm2Co17), hard Ferrite (HF) and sintered Aluminum-Nickel-Cobalt (AlNiCo).

Each of these magnetic materials has properties that distinguish them from each other, which can be selected from the following characteristics:

- Energy density (or energy product BH);

- Coercivity (the strength of the magnetic field necessary for the complete demagnetization of a ferromagnetic material);

- Temperature stability;

- Electrical resistance;

- Corrosion resistance;

- Thermal conductivity;

- Costs.

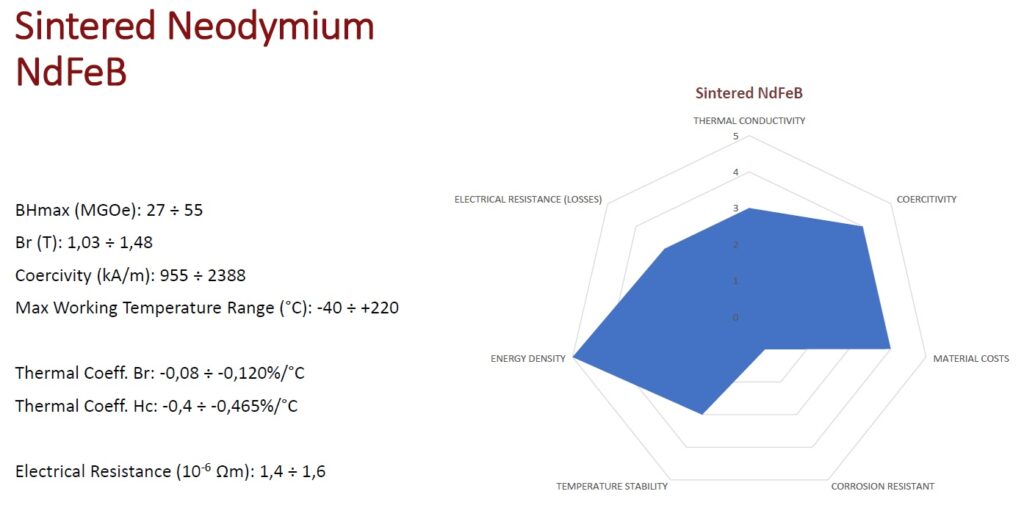

Sintered neodymium (NdFeB) has a high energy density (high Br and BH values) and good coercivity (HcJ), as well as good resistance to temperatures (-40 ° / + 220 ° C).

Therefore, they are suitable for use in applications where the presence of a high magnetic field is essential, such as electric motors, alternators and generators, medical applications, separation and lifting systems for the mining industry, etc.

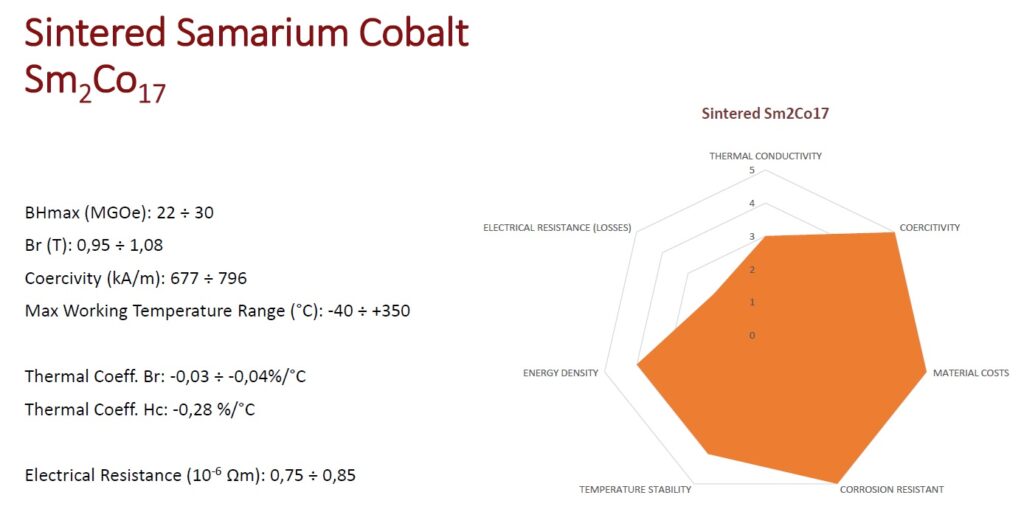

Sintered Samarium Cobalt (Sm2Co17), unlike Neodymium, is a very resistant material to corrosion and has a high resistance to temperatures (up to + 350 ° C).

They also have a good energy density (Br and BH values) and thanks to these characteristics they are used in applications where the magnet is in contact with liquids or chemical fluids, at high operating temperatures and which require generous magnetic performance.

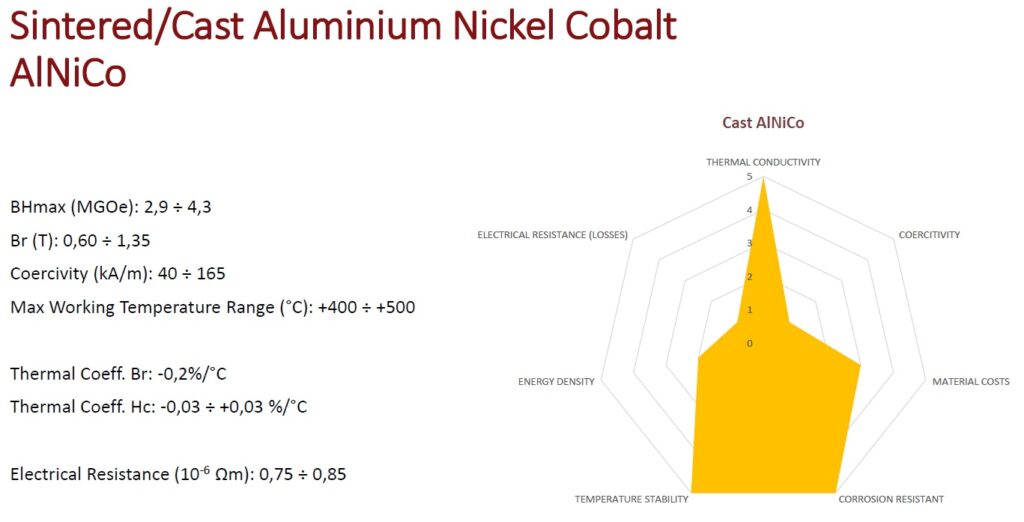

Sintered AlNiCo magnets consist of an alloy of Aluminum (Al), Nickel (Ni) and Cobalt (Co).

Like sintered ferrite magnetic materials, they are very resistant to corrosion. In addition, they are characterized by high temperature stability and have good thermal conductivity.

They are made by melting the material (shell casting technology) or by sintering, depending on the magnetic properties required.

Thanks to these characteristics, they are mainly used in sensors and measuring instruments, in electromechanical relays, magnetic lifters, etc.

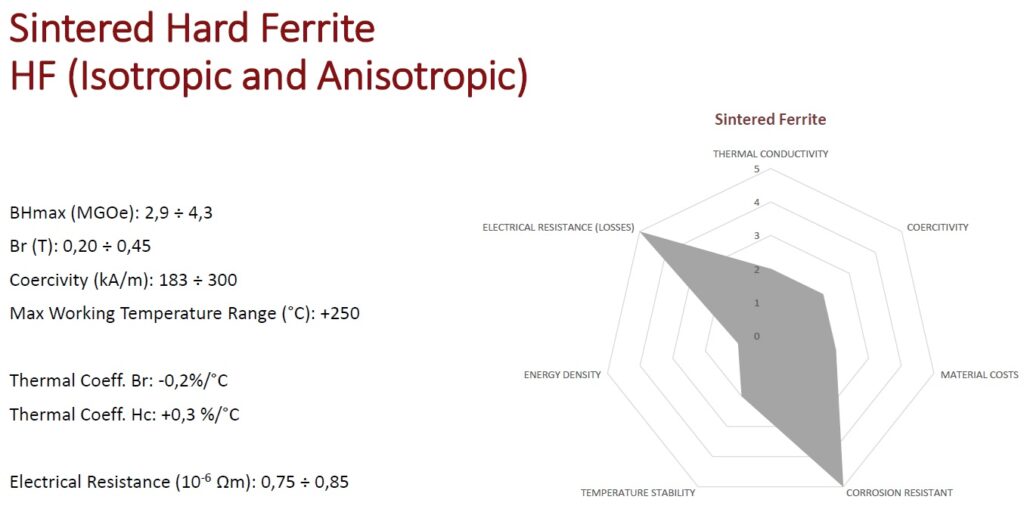

Sintered Ferrite magnets are among the first magnetic materials born, and among the cheapest.

They do not require any coating as they are naturally resistant to oxidation and have a high level of electrical resistance.

They are divided into two versions: Isotropic Ferrite or Anisotropic Ferrite depending on the production process:

- isotropic ferrite: occurs through the cold and “dry” pressing of the material. In this case the magnet can be magnetized in all directions, but the energy density remains low.

- anisotropic ferrite: made by pressing the powders mixed with liquid catalysts (“wet” process). In this case, the powder mix (iron oxide + Sr or Ba carbonate) must be pre-oriented by a magnetic field during the pressing phase and can subsequently be magnetized following the required magnetization configuration.

The main materials, such as Neodymium, Samarium Cobalt and Ferrite, can be mixed with plastic binders (polyamides) or with epoxy resins, to make plasto-magnets, which we will deepen in a future article.

For more information consult our catalog and contact us at info@garnetitalia.com