TYPES OF PLASTIC MAGNETS:

Among the various types of magnets, plastic magnets are the most recent and innovative on the permanent magnets market. They are divided into two types:

INJECTION MOLDED MAGNETS:

They are made using an injection molding process, mixing magnetic powders with synthetic polymers (polyamides).

The materials made with this technology are:

- Injection Plasto Ferrite;

- Injection Plasto Neodymium;

- Injection Plasto Samarium Cobalt.

Thanks to the injection molding process, complex shapes (such as rings with grooves / teeth, toothed wheels) with high mechanical precision can be obtained. They are in fact widely used in the sensor sector (including Automotive) for the construction of ABS sensors, logometers, or miniaturized electric motors, etc.

It is also possible to carry out co-molding with other components in order to obtain semi-finished systems, (eg complete rotors for electric motors or targets for hall sensors) and therefore simplify or avoid further production processes.

The maximum working temperature (Tw) varies according to the plastic binder that you decide to use:

- PA6: Tw + 150 ° C

- PA12: Tw + 120 ° C

- PPS: Tw + 180 ° C

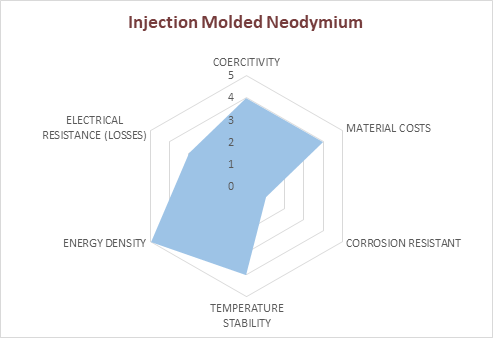

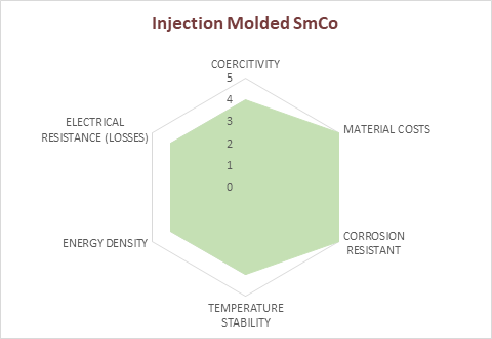

Below is a summary of their main features:

BONDED MAGNETS

Obtained through the cold compression of magnetic powders and thermoplastic resins, they are the plastic magnets with the highest performance available on the market.

The material versions available are as follows:

- Plasto NdFeB Compressed (Bonded NdFeB);

- Plasto SmCo Compressed (Bonded SmCo).

With cold compressed plastic magnets it is possible to obtain semi-complex shapes such as multipolar rings for the construction of rotors for small size motors, or of DC motor stators by replacing the ferrite and therefore optimizing the weights and dimensions of the stator part. They are also widely used for the construction of magnetic encoders or rotary sensors in general.

The possibility of coatings in epoxy resin or Parylene allows them to be used also in applications that involve direct, not prolonged contact with water or other non-corrosive liquids.

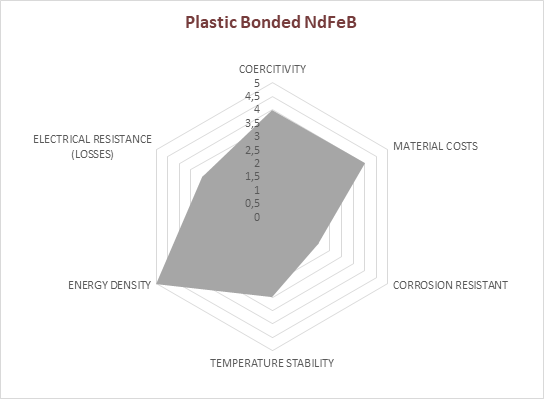

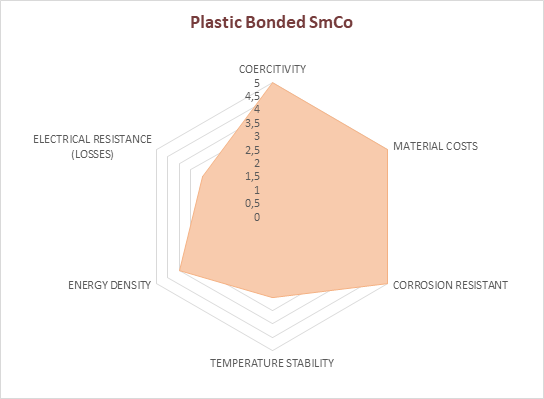

Below is a summary of their main features:

For more information contact us at info@garnetitalia.com.