RARE EARTHS

Rare earths are a group of 17 chemical elements of the periodic table considered strategic material for the production of permanent magnets used in many industrial sectors.

In particular, sintered neodymium magnets (NdFeB) are the most popular on the market.

The alternative magnetic materials available can be samarium-cobalt, compressed plasto-neodymium and injected plasto-neodymium (bonded and injection molding), also available on ferrite base, and magnetic materials in aluminum-nickel-cobalt (AlNiCo).

After a period of relative prices stability, in the last weeks main rare earths prices are progressively and rapidly rising.

Factories send quotes with a validity of 1, 2 days because of the strong instability. Main magnet manufacturers and production chain (e.g. coating) have completely overbooked their production lines.

We strongly suggest to our clients to plan their magnet purchases in advance and to book the production as soon as possible, in order to protect themselves from further cost increases. We also recommend to prefer sea or combined sea-air shipments rather than air transport, to avoid cost supplements

Our Sales Department is at your complete disposal to develop customized purchase plans in line with your production needs.

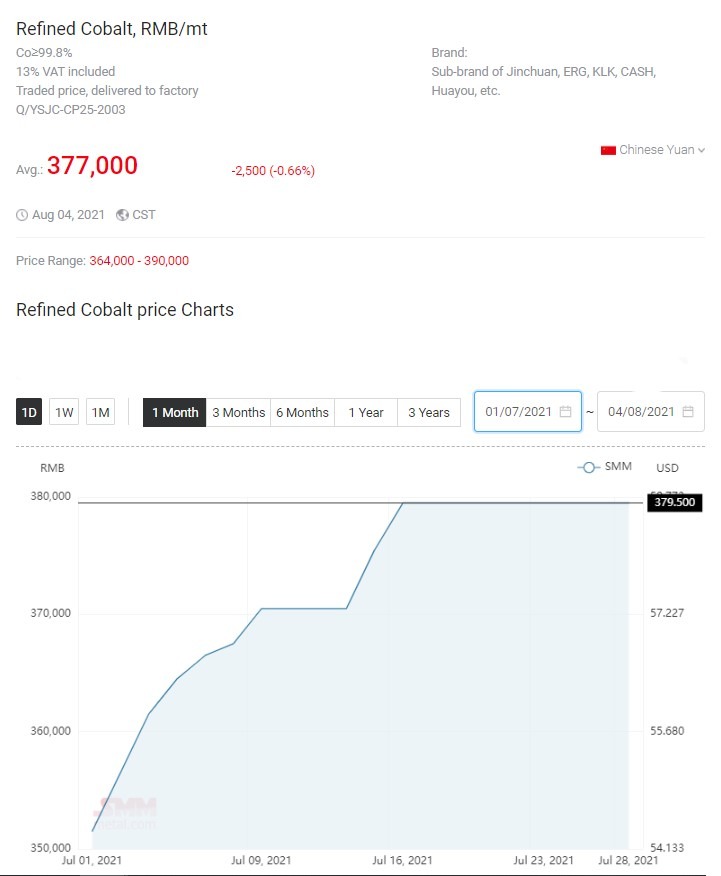

Below is showed the main raw materials update prices used for the production of rare earth magnets. The cost of permanent magnets as a finished product is inevitably influenced by the trend in the price of raw materials, indicated in RMB / Ton in the following graphs.

Dysprosium – Iron Alloy:

Praseodynium – Neodymium Alloy:

Cobalt: